Teagle

Technological advancement in machinery also plays a significant factor in Agri-tech; in a rapidly changing agricultural sector, machinery is crucial for the avoidance of production losses, and in the face of an ever increasing challenge in the availability of labour.

In economically challenging times there has been a dramatic downturn in the demand for farm machinery with reductions in turnover of up to 20%. Teagle, a Cornwall based agricultural machinery manufacturer, has faced these challenges head on, by maintaining high quality production and an commitment to product development which has been ongoing since the company’s establishment some 70 years ago.

The Agri-tech Cornwall Innovation Grant Project has been able to assist Teagle in their product development by part investing in R&D equipment to relieve the pressure of manufacturing prototypes on production equipment.

Currently, R&D parts have to wait for the availability of a hydraulic press to form them which causes delays and also significant interruption to production. This capital equipment is costly, but nonetheless demonstrates the commitment to the client base. The addition of this new equipment means that R&D parts can be made off-line, without causing production downtime and greatly reducing the lead-time of producing new prototype machines.

The grant is enabling Teagle to increase product market share, as well as engage with a broader spectrum of clientele locally and nationally by increasing the company’s ability to cater for wider needs.

2 Minute Farmer (2MF)

Some farms will always perform better than others, but why is there such a gulf between the performance of the top and bottom 25%? The former make an average annual profit of £124k; the latter’s losses average £9k. The 2-Minute Farmer (2MF) project wanted to find out, firstly, what lay behind this disparity and, secondly, how to help farmers, in efficient, two-minute bursts, to assess and improve their farms.

The project sought to increase farmer engagement with topics like succession planning, cashflow, workload, technical efficiency and farmer wellbeing (agriculture has a higher suicide rate than any other sector). This involved developing self-assessment tools that farming-related businesses could use to assess and then improve their technical and business knowledge.

Significant barriers to this included a lack of engagement, especially among those businesses not in the top 25%; hardly surprising, given that a farmer’s average working week is 65 hours. This, along with budget and time constraints, explained the project’s focus on the Tractor Wheel of Life, a self-assessment tool which enables farmers to benchmark their personal, technical and business performance and signposts them to useful resources.

2MF co-designed the tool with farmers, although feedback was restricted due to Covid ruling out face-to-face events. The tool breaks farming down into ten themes; each has a 2-Minute self-assessment whose results lead to goal-setting, sign-posting and the start of conversations around important issues.

Because agriculture is undergoing such rapid change, it’s more important than ever that farmers – especially those only just surviving – get the help they need to improve their business’s resilience and efficiency, as well as their own wellbeing. The project’s research showed a preference among farmers for a conversational style of learning, a finding reinforced by very positive feedback at local events, especially among farmers described as being in the middle 50% of farm performers and justifiably classifiable as ‘harder to reach’.

Taking all this into account, 2MF’s design – easily-understood, quick to complete, reflecting farmers’ actual experience – has helped farmers across the south west gain a better understanding of the challenges they face and the range of practical means available to help overcome them.

For more information please go to 2MF website.

Lobster Genes

Developing Genetic Assignment Resources for Lobster Conservation and Fisheries Traceability

The project aimed to help lobster hatcheries to ensure they were managed in an ecologically and economically sustainable way. The motivation for this was that although hatcheries have reaped the benefits of the species’ population enhancement, their successes have also had some unintended consequences, not all of them beneficial.

In short, the importance of proper genetic management has sometimes been overlooked, mainly because the only available tools to distinguish recaptured hatchery individuals from their natural counterparts have been expensive and unreliable.

The genetic screening techniques we developed and tested enable lobsters to be identified in three ways: by species, population and family. These categories help with aquaculture development and stock conservation, as well as seafood traceability. Practically, this means potentially-invasive American lobsters can be distinguished from their European counterparts; it means enabling the establishment of regional provenance among catches; and it also means accurate identifications of pedigrees, parentage and sibships to foster the optimum levels of selective breeding and inbreeding.

Over and above these goals (and although not our primary aims), our work helped develop knowledge and tools which, industry-wide, would help with conservation management, product traceability and best-practice in new stocking efforts. The European lobster is, pound-for-pound, Britain’s most valuable commercial seafood, and our industrial collaborators in Cornwall – the National Lobster Hatchery in Padstow and Wing of St Mawes in Indian Queens – saw our ability to provide this genetic analysis commercially as being key to their businesses’ long-term viability and success.

The project delivered on all of its original ambitions, providing a trio of genetic assignment tools, whose commercial applications became very clear as the project developed, and which will mean conservation measures can be focused on native rather invasive species (and, by extension, could lead to producers, processors and retailers being able to prove the provenance of what we’re eating).

We’re now actively pursuing plans with potential customers to put these resources into practice; it also means the project more broadly will have lasting impacts on fields as varied as biological conservation, aquaculture development, as well as fisheries traceability.

To find out more please email Alex Huke at a.r.huke@exeter.ac.uk or call us on 01326 255844.

Farm Visualisation (VizAg)

To improve efficiency and sustainability, farmers make increasing use of data gathered on-farm; they’re helped to do this by proliferating technologies which collect, sense and interpret this data. Although this means opportunities for businesses which interpret, integrate and visualise data, it’s not always a smooth or reliable process. Data collection can be impractical, costly, and, even if successfully completed, data needs to be turned into useable information for the farmer.

So this project’s aim was threefold: to keep data-collection to a bare, cost-effective minimum; to generate it using a proven agricultural model; and to develop visualisation tools to keep the farmer usefully and practically informed.

Rothamsted Research (RRes) and Glas Data were our collaborators in the project, which was negatively impacted by various factors outside our control. Employing a highly experienced postdoctoral researcher took longer than anticipated (for Visa reasons), and RRes were unable to retain them once in post. A replacement was hard to find (in part due to the high demand for such skillsets) and the alternatives – secondments, joint appointments, consultancies – proved not to be feasible.

Covid’s impact was huge too. Glas Data had to furlough staff so couldn’t develop a full-visualised model; the previous, web-based prototype had to be used to engage farm businesses in testing and development, a process which, along with other industry events, exhibits, and knowledge-exchange opportunities, was also curtailed by lockdowns and travel restrictions.

The project’s work focused on a light-weight version of the well-established SPACSYS model which has been central to numerous research projects for 20 years. Outputs consisted of crop productivity, soil carbon and nitrogen budgets, soil water content and water discharge through surface run-off and drainage, and expected financial gains/losses (most of which are not readily available in existing management tools).

Although constraints restricted scope to a prototype web-based form, RRes and Glas Data collaborated well and intend to again, especially in light of the reception at workshops and events for the idea of developing a SPACSYS-based decision support tool for on-farm monitoring. The considerable technical expertise already involved in this project has resulted in a valuable first step being taken. Further steps and future progression and collaboration (in the form of this decision support tool) are exciting and likely.

To find out more, please email us at vishnu.paranthaman@rothamsted.ac.uk or call us on +44 (0) 1837 512 272

Starlings

Reducing starling impacts in cattle housing

This project’s main aim was to reduce the damage caused by starlings to Cornish dairy farms by trialling a new technology called Sonic Nets.

Associated with this primary aim were other objectives: to engage with local technical businesses who could design, refine, and manufacture Sonic Nets technology to bring it to market; to engage with regional farming equipment suppliers and pest control businesses who would sell or use Sonic Nets; and to better understand the potential spread of anti-microbial resistance (AMR) within and between farms, assess starlings’ role in this, and find out if Sonic Nets might reduce the problem. (The potential benefits of this last aim include reducing costs to farmers and restricting the spread of drug-resistant pathogens, with implications for human and livestock health globally.)

We ended up needing to extend the project because starling damage is seasonal, and there was limited time available to design, pilot, and complete trials in the first few months of the project before winter starling flocks dispersed.

Fundamental to the project’s success was the expert input of Professor John Swaddle at the College of William and Mary, Williamsburg, USA. Prof. Swaddle and his research group, as well as APT-GB Ltd. based in Liskeard (who built loudspeakers 90% cheaper than commercial hardware) and Be-Ta-Pest and Terminate, pest control businesses based in Falmouth and Mylor, respectively.

Farmers, however, were crucial to the project. Trials took place on 13 farms in total, and around 30 other farmers had initially helped us build a picture of starling-damage in the area and their experience of existing deterrent technology.

It could be argued that the pandemic has helped raise the importance of the project’s focus on AMR, and that, as a result, its outcomes could prove to have global significance. Specifically, and shorter term, the project succeeded in trialling a new technology in a novel setting; farmers, pest control businesses, and technology businesses have benefitted from collaborating with, or participating in, the project. As well as benefiting these partners, Sonic Nets technology has the potential to be used across regions and sectors where existing technology is failing to halt pest problems.

To find out more please email Alex Huke at a.r.huke@exeter.ac.uk or call us on 01326 255844.

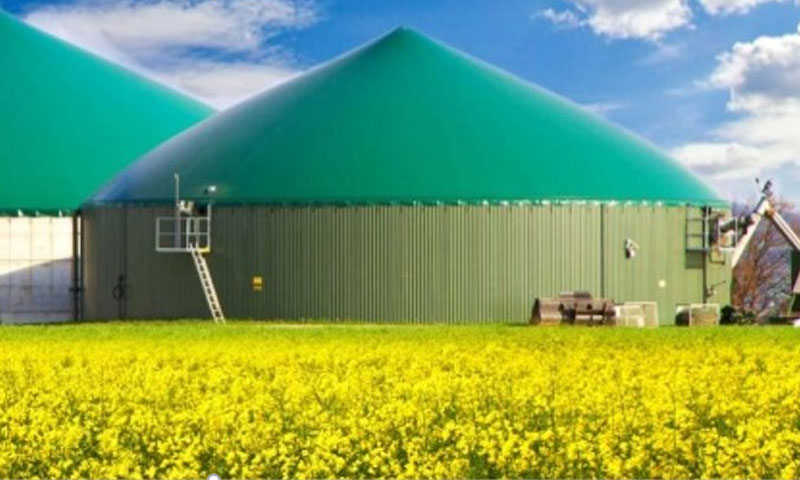

Anaerobic Digestion (AD)

Biogas produced by Anaerobic Digestion (AD) is an increasingly important renewable energy in Cornwall and beyond. This project was designed to help ensure that biogas is produced in the most stable and predictable ways, taking into account all the variations in the feed which goes in to the AD reactors.

Its aim was to build up a detailed picture of the various microbes in a wide range of industrial AD digesters and, having done so, to learn about the impact of what goes in on what comes out. The more detailed the picture that’s built, the likelier it is – once the project’s findings are communicated – that the industry will be able to improve its day-to-day control of the process.

The nature of AD means that digesters play an important part in their local communities. Because they take in (e.g.) manure, sewage, food and organic waste, in varying combinations, they’re an important part of any local economy aspiring to be more circular.

This project was also keen to look at AD’s less obvious benefits to local communities, by testing the capacity of AD plants to reduce the load of antibiotic-resistant genes and pathogens on the environment.

A workshop was attended by representatives of five AD businesses and dealt with the microbiology of AD and its role within the circular economy framework. Experiments arising from these meetings yielded findings which were presented locally, nationally and internationally, although their main results – and two publications based on them – have been delayed by a slow turnover of sequencing data.

The project saw the forging of valuable, long-lasting relationships, and has cemented links between science and industry. Businesses thirsty for innovation often look to academics for inspiration, just as academics need to see what happens to their laboratory-size ideas in life-size AD fermenters; this project has both formalised this reciprocity and established partnerships which will be sustainable well into the future.

All of which means a local hub for AD-related expertise has been another key outcome of the project, along with a mutual trust and confidence between industry and science which means the promise of more funding and further important research.

To find out more please email Alex Huke at a.r.huke@exeter.ac.uk or call us on 01326 255844.

Viticulture

Growing grapes in the UK is difficult. Spring is a vital time for vines because it’s when flowering happens and so is a good indicator of the coming season’s yield. But our cool, wet springs – and generally unpredictable weather – often mean low yields and hard work making a profit.

This is not just bad news for ripening grapes; cool, wet springs hamper growth, but cool, wet summers allow fungal and bacterial pathogens, like Botrytis, to flourish, so expensive disease-management also impacts profit margins. The last 30 years’ average yield in the UK has been 3.3 tonnes of grapes per hectare; the break-even figure is estimated at around 3.8 tonnes (the average in Champagne is 10 tonnes).

This project aimed to develop a cloche system to offset these factors; it was undertaken in collaboration with SmartVit, a viticulture consulting business based in Truro, Cornwall.

We worked with three Cornish vineyards with differing micro-climates to test the cloche system, measuring its impact on grape-growth and infection by Botrytis. In 2018, this involved setting up trials to assess whether: 1. cloche can improve yield generally, 2. vines under cloche suffer reduced disease from Botrytis, and 3. cloche interacts with Botrytis biocontrol agents Prestop and Serenade.

The subsequent two years confirmed why it’s so hard to grow grapes in Cornwall. Our vineyards suffered the destruction of cloche by spring storms, the complete loss of harvests to spring frosts, and large-scale outbreaks of slugs and snails. In light of these developments we changed the scope of our trials.

Overall, both cloche and mowing were shown to have desirable impacts on pest management and vine growth. Grapes ripened faster, were bigger, and had higher sugar content, though total overall yield was not significantly different to open treatments.

Evidence of biocontrol’s efficacy against botrytis and molluscs was more equivocal. Sites differed significantly in disease response, and botrytis was substantially more damaging under cloche at one site than the other. Neither Prestop nor Serenade significantly impacted yield or Botrytis prevalence, though Prestop appears to have limited between-berry spread in infected bunches. Over the course of the project we developed strong ties with Cornish growers, ties which will continue to be important in developing future projects in Cornwall.

To find out more please email Alex Huke at a.r.huke@exeter.ac.uk or call us on 01326 255844.

ClimateHub

New and high-value crops are increasingly thriving thanks to recent temperature-rises. As the climate keeps changing, so new crops will become viable, and those currently grown in small quantities will be able to be cultivated more widely. However, they need specific microclimatic conditions to thrive. Being able to identify exactly the best places for them will maximise their chances of success: standard temperature sensors can’taccurately measure temperatures relatively close to the ground in direct sunlight.

Climatehub developed state-of-the art farm-and field-scale climate and crop models to show the specific areas of Cornwall and the Isles of Scilly bestsuited to growing such crops, now and in future. Our project partner, Farm Cornwall, is using the maps developed to deliver sound, practical advice to farmers and horticulturalists.

In partnership with Empowerment Innovation & Resource Ltd, we designed a new temperature-sensor capable of accurately measuring microclimatic conditions. The product underwent field testing in Cornwall and prototypes are being tested across Europe, although bringing the product to market has been complicated by our business partner’s insolvency.

Alongside the sensor, the project yielded open-source software forhigh-resolution climate modellingand for high-resolution crop suitability modelling, as well as developing climate and crop suitability maps. Climatehub has also triggered inward investment and skills to Cornwall: a Research Council-funded PhDand funding from Defra to use the same climate models to assess crop pest and disease risk.

We achieved our main aim, to develop and make publicly available crop suitability maps for Cornwall and the Isles of Scilly, and to embed these web platform to help Farm Cornwall (even though the development of a thermal sensor was hampered by our partner’s financial difficulties).

And the work done on the sensor helped us develop a low power-consumption, battery-operated data logger with much wider applications than thermal sensing. We are exploring market opportunities and partner businesses with whom to work on further development of, and potential applications for, this device.

To find out more please email Alex Huke at a.r.huke@exeter.ac.uk or call us on 01326 255844.

Innovation at Chapman Machinery

James Chapman’s firm has expanded from being a one-man band when he launched it in 2010 to one that now employs about 10 people.

It makes and sells agricultural, equestrian and horticultural kit, primarily specialising in items that tow behind ATVs, UTVs or 4x4s – everything from mowers and mounted feeders to bale transporter and weed wipers.

Based near Bude in Cornwall, the firm has ambitious plans and has been helped by an ACP Innovation Grant to buy a new press brake machine allowing it to develop prototypes on-site more quickly and easily.

The piece of equipment cost the best part of £100,000, but about half of that came from ACP – and its arrival will speed the company’s R&D capabilities, helping drive business growth and long-term success.

To find out more, please email Cornwall Development Company or call us on +44 (0) 1872 322672.

PhosField

This project’s remit was to develop a rapid soil-phosphate measurement toolkit, which was crucial for several reasons. Firstly, phosphate sources are limited; any tool helping farmers to use it more precisely avoids unnecessary depletion of this natural resource.

Secondly, moving from prophylactic over-use to more precise, targeted applications of phosphate would reduce the volumes of phosphate which end up polluting watercourses.

Thirdly, such a tool would directly benefit farmers: cheaper, more frequent and accurate soil-testing means they use fertiliser only where and when needed, resulting in increased yields, less work and lower costs.

Early work towards this goal saw Rothamsted Research, (RRes) collaborate with a Cornish environmental sensor business. The challenges encountered – the sensor’s inability to detect phosphates in a soil sample using water as an extractant, high levels of interference from nitrate – meant this collaboration ended early.

However, the team at RRes continued, and began a collaboration with Grassland Resource and Improvements, a Cornish agronomist, to find a network of Cornish farms and growers to sample soils and trial new strategies. A company called Phosfield Limited was established in 2019. Part of their work – and of the project’s remit – involved developing fertiliser recommendations so that those using the kits would know which fertilisers worked best on which soil types.

Covid meant visits, workshops and training events had to be cancelled, as did the researchers’ trip to test the prototype kit in Ghana, where Agricultural Extension workers provided feedback about its useability. This input, along with soil-testing in the UK, led to the kit and testing protocol being tweaked and improved in light of user experiences. It also means researchers are better equipped to adapt the test for use in developing countries.

Overall, the project has successfully produced a prototype rapid soil-phosphate measurement toolkit which will enable cheaper, more frequent testing as well as more precise fertiliser applications, maximising yields and reducing pollution. The issues described above, along with Covid, have left a gap between prototype-development and product-launch, but working with a product design company has definitely enhanced the prototype test kit, making it more user friendly and nearer to market. As a result, Phosfield Ltd is actively moving this forward in collaboration with the RRes Innovation and Commercialisation Office.

To find out more, please email us at martin.blackwell@rothamsted.ac.uk or call us on +44 (0)1837 512 322

.